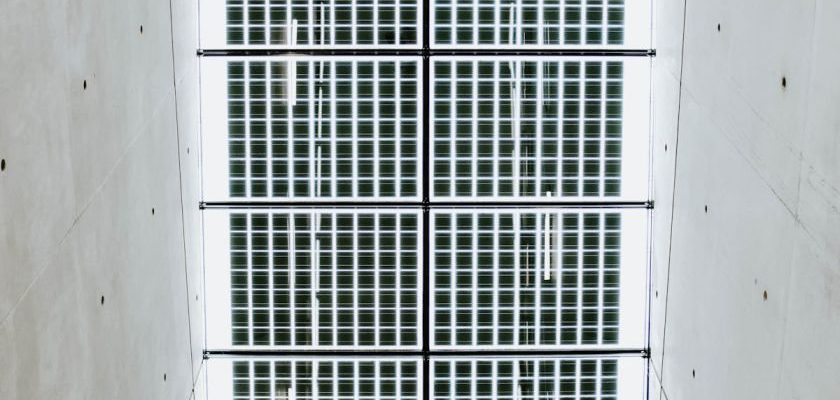

Effective industrial ventilation plays a crucial role in maintaining a safe and healthy work environment for employees while also ensuring optimal productivity. Proper ventilation systems can help control indoor air quality, remove contaminants, and regulate temperature and humidity levels. To achieve these benefits, various techniques can be employed to ensure that industrial ventilation systems work efficiently and effectively.

Understanding Airflow Patterns

One of the fundamental techniques for effective industrial ventilation is to understand the airflow patterns within the workplace. By analyzing the movement of air, including the sources of contaminants and how they disperse, ventilation systems can be strategically designed to capture and remove pollutants effectively. Utilizing computational fluid dynamics (CFD) modeling can help in visualizing airflow patterns and optimizing ventilation system layouts.

Local Exhaust Ventilation

Local exhaust ventilation (LEV) systems are designed to capture contaminants at the source before they can disperse into the wider work environment. This technique involves using hoods, ducts, and fans to extract pollutants directly from equipment or processes, preventing them from circulating throughout the workspace. Proper placement and sizing of LEV systems are critical to their effectiveness in reducing worker exposure to harmful substances.

Dilution Ventilation

Dilution ventilation involves introducing clean, fresh air into the workspace to dilute and remove contaminants. This technique relies on the principle of mixing clean air with polluted air to reduce the concentration of harmful substances. Proper airflow rates and ventilation design are essential for dilution ventilation systems to effectively control indoor air quality and maintain a comfortable working environment.

Natural Ventilation

In some industrial settings, natural ventilation can be a cost-effective and energy-efficient solution for providing adequate airflow. Natural ventilation utilizes openings such as windows, doors, and vents to facilitate the exchange of indoor and outdoor air. By harnessing natural airflow patterns, industrial facilities can reduce the reliance on mechanical ventilation systems and lower energy consumption.

Regular Maintenance and Monitoring

To ensure the continued effectiveness of industrial ventilation systems, regular maintenance and monitoring are essential. Filters, fans, ducts, and other components should be inspected and cleaned on a routine basis to prevent blockages and malfunctions. Monitoring air quality parameters and ventilation system performance can help identify potential issues early and make necessary adjustments to maintain a safe and healthy work environment.

In conclusion, effective industrial ventilation involves a combination of techniques tailored to the specific needs of the workplace. By understanding airflow patterns, utilizing local exhaust and dilution ventilation, incorporating natural ventilation where applicable, and implementing regular maintenance practices, industrial facilities can create a safe and productive environment for their employees. Prioritizing ventilation system design and maintenance is crucial in safeguarding the health and well-being of workers while optimizing operational efficiency.