In the fast-paced world of industry, technological advancements continue to revolutionize processes and enhance efficiency. One such innovation that has significantly impacted various sectors is thermal imaging. By utilizing infrared technology to detect heat signatures, thermal imaging has found a multitude of applications in industry, providing valuable insights and improving productivity across different fields.

Enhancing Safety and Preventive Maintenance

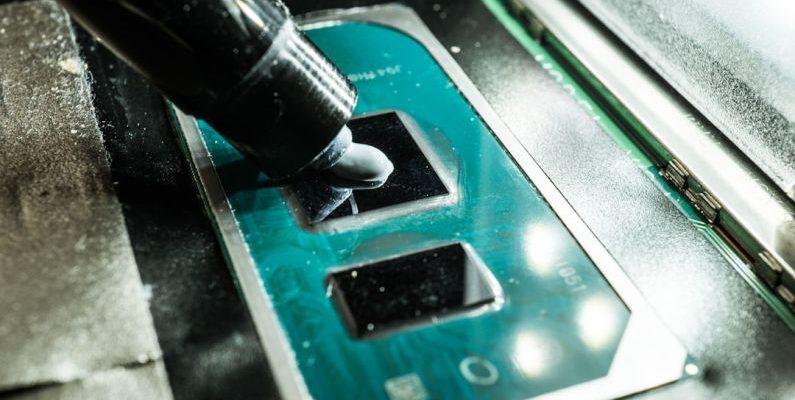

One of the primary applications of thermal imaging in industry is enhancing safety measures and facilitating preventive maintenance. By detecting abnormal temperature patterns, thermal imaging enables early identification of potential equipment malfunctions or failures. This proactive approach allows maintenance teams to address issues before they escalate, minimizing downtime and preventing costly breakdowns. Additionally, thermal imaging can identify overheating components in electrical systems, helping to prevent fires and ensuring worker safety.

Quality Control and Process Optimization

Thermal imaging plays a crucial role in quality control and process optimization within industrial settings. By capturing thermal images of products during manufacturing processes, defects and irregularities can be quickly identified. This real-time feedback enables operators to make immediate adjustments, ensuring that products meet quality standards and reducing waste. Furthermore, thermal imaging can be used to monitor and optimize thermal processes such as heat treatment and welding, leading to improved efficiency and product quality.

Energy Efficiency and Building Inspections

In the realm of energy management, thermal imaging is a valuable tool for assessing building energy efficiency and conducting inspections. By identifying areas of heat loss or air leakage, thermal imaging helps in pinpointing energy inefficiencies in structures. This information can then be used to implement targeted improvements, such as enhancing insulation or sealing gaps, leading to reduced energy consumption and cost savings. Moreover, thermal imaging is utilized in building inspections to detect moisture intrusion, insulation defects, and structural anomalies, aiding in the early detection of potential issues and ensuring building integrity.

Predictive Maintenance and Asset Management

Predictive maintenance is a key strategy employed by industries to optimize equipment performance and extend asset lifespan. Thermal imaging enables predictive maintenance by detecting anomalies in machinery and equipment before they lead to failures. By monitoring temperature variations and identifying potential faults, maintenance schedules can be planned more effectively, reducing downtime and prolonging the life of assets. This proactive approach to maintenance not only enhances operational efficiency but also saves costs in the long run.

Incorporating thermal imaging technology into industrial processes has proven to be a game-changer, offering a range of benefits from safety enhancement to cost savings. As industries continue to embrace innovation, the applications of thermal imaging are expected to expand further, driving efficiency, productivity, and competitiveness across sectors.