In recent years, the automotive industry has seen a significant rise in the adoption of robotics to enhance efficiency, safety, and innovation in vehicle manufacturing processes. From automated assembly lines to collaborative robots working alongside human workers, the latest trends in automotive robotics are revolutionizing the way cars are built and operated. Let’s delve into some of the key developments shaping the future of automotive robotics.

**Autonomous Guided Vehicles (AGVs)**

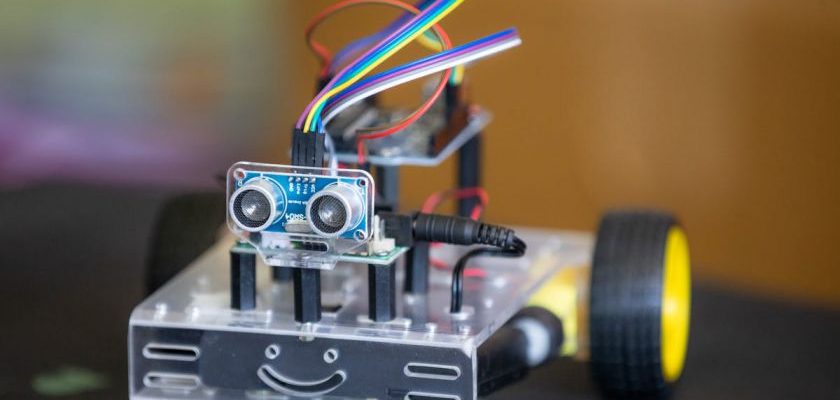

One of the most prominent trends in automotive robotics is the integration of Autonomous Guided Vehicles (AGVs) in manufacturing facilities. These self-driving vehicles are equipped with sensors and cameras that enable them to navigate production floors, transport materials, and assist in various tasks without the need for human intervention. AGVs are enhancing efficiency by streamlining logistics operations and reducing the risk of accidents in busy factory environments.

**Cobots – Collaborative Robots**

Collaborative robots, or cobots, are another key trend in automotive robotics. Unlike traditional industrial robots that are confined to cages for safety reasons, cobots are designed to work alongside human operators in a shared workspace. These robots are equipped with advanced sensors that allow them to detect and react to the presence of humans, making them safe and ideal for tasks that require human-robot collaboration. Cobots are being used in various automotive manufacturing processes, from assembly and painting to quality control and packaging.

**Artificial Intelligence and Machine Learning**

Advancements in artificial intelligence (AI) and machine learning are driving innovation in automotive robotics. AI-powered robots are being used for tasks such as predictive maintenance, quality inspection, and adaptive manufacturing processes. Machine learning algorithms enable robots to analyze data, learn from experience, and continuously improve their performance over time. This trend is leading to the development of intelligent robots that can adapt to changing production requirements and optimize efficiency in automotive plants.

**3D Printing and Additive Manufacturing**

3D printing and additive manufacturing technologies are revolutionizing the automotive industry by enabling the production of complex parts with precision and efficiency. Robotic arms equipped with 3D printers are being used to create custom components, prototypes, and tooling in a fraction of the time it would take using traditional manufacturing methods. This trend is driving innovation in automotive design and production, allowing manufacturers to reduce costs, improve flexibility, and accelerate time-to-market.

**In Conclusion**

The latest trends in automotive robotics are reshaping the industry by enhancing automation, safety, and efficiency in manufacturing processes. From AGVs and cobots to AI-powered robots and additive manufacturing technologies, the integration of robotics is driving innovation and transforming the way vehicles are designed, built, and operated. As the automotive industry continues to evolve, we can expect to see even more exciting developments in robotics that will further revolutionize the future of mobility.