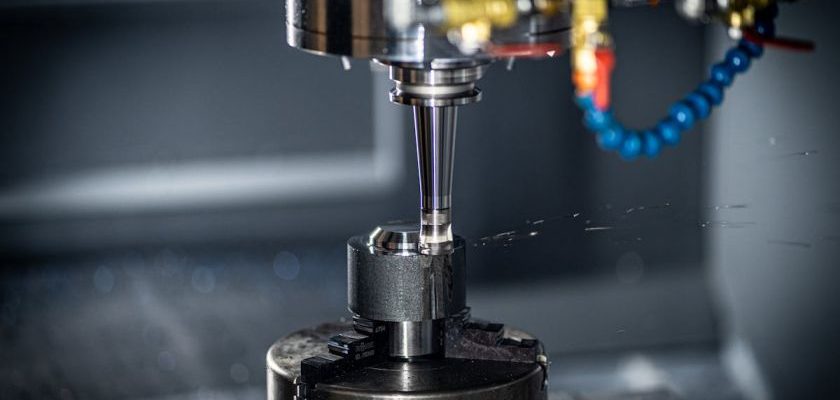

In the world of manufacturing, CNC machining has long been the go-to method for producing precision parts with high efficiency. However, as businesses seek to cut costs and explore more sustainable practices, the question arises: Is there a cost-effective alternative to CNC machining? Let’s delve into this topic and explore some possible solutions.

The Rise of 3D Printing in Manufacturing

One of the most notable alternatives to CNC machining is 3D printing, also known as additive manufacturing. 3D printing has gained significant traction in recent years due to its ability to create complex geometries quickly and cost-effectively. Unlike CNC machining, which involves subtracting material from a solid block, 3D printing builds parts layer by layer, reducing material waste and allowing for greater design flexibility.

3D printing is particularly well-suited for producing prototypes and low-volume production runs, making it an attractive option for businesses looking to test new designs or bring products to market quickly. While CNC machining excels in high-volume production due to its speed and precision, 3D printing offers a more economical solution for smaller batch sizes.

Material Selection and Surface Finish

One key consideration when evaluating alternatives to CNC machining is the choice of materials and the desired surface finish of the parts. CNC machining is compatible with a wide range of materials, including metals, plastics, and composites, and can achieve tight tolerances and smooth surface finishes. In comparison, 3D printing has limitations in material selection and may not always deliver the same level of surface finish as CNC machining.

However, advancements in 3D printing technology have led to the development of new materials and processes that bridge the gap with traditional machining methods. For example, metal 3D printing, also known as additive metal manufacturing, enables the production of complex metal parts with high precision, opening up new possibilities for industries such as aerospace, automotive, and healthcare.

Cost Considerations and Scalability

When evaluating the cost-effectiveness of alternatives to CNC machining, businesses must consider factors such as equipment costs, material expenses, labor requirements, and production scalability. While CNC machining requires significant upfront investment in machinery and tooling, 3D printing equipment is generally more affordable and accessible, especially for small to medium-sized enterprises.

Additionally, 3D printing offers the advantage of producing parts on-demand, eliminating the need for costly inventory storage and reducing lead times. This scalability makes 3D printing an attractive option for businesses seeking to streamline their production processes and respond quickly to changing market demands.

Exploring Hybrid Manufacturing Approaches

In conclusion, while CNC machining remains a powerful tool for high-volume production and precision machining, businesses can benefit from exploring cost-effective alternatives such as 3D printing. By leveraging the strengths of both technologies and adopting a hybrid manufacturing approach, companies can optimize their production workflows, reduce costs, and stay competitive in a rapidly evolving marketplace.