Industrial robotics has revolutionized the manufacturing industry, leading to increased efficiency, accuracy, and productivity in various sectors. These robotic systems are built on specific principles that govern their design, functionality, and applications. Understanding the principles behind industrial robotics is crucial for engineers, manufacturers, and anyone interested in the future of automation.

Evolution of Industrial Robotics

The concept of industrial robotics dates back to the early 20th century when the first programmable robot, Unimate, was introduced in the 1950s. Since then, industrial robots have undergone significant advancements in terms of technology, capabilities, and versatility. Today, these machines play a vital role in tasks ranging from assembly and welding to material handling and packaging.

Adaptability and Flexibility

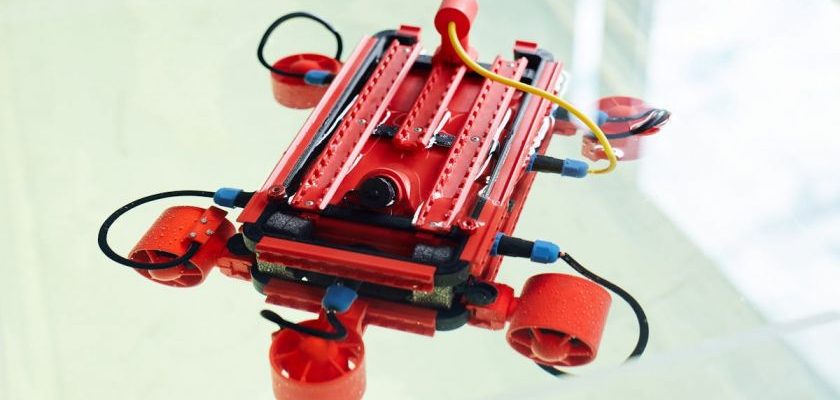

One of the key principles behind industrial robotics is adaptability. Modern robots are designed to perform a wide range of tasks in diverse environments, thanks to their programmable nature and advanced sensors. This adaptability allows manufacturers to reconfigure robots quickly for different production processes, leading to enhanced flexibility in manufacturing operations.

Precision and Accuracy

Industrial robots are known for their exceptional precision and accuracy, which are critical for tasks that require consistent quality and repeatability. By leveraging advanced control systems and high-resolution sensors, robots can perform intricate operations with minimal margin of error. This principle is particularly essential in industries such as electronics, automotive, and aerospace, where precision is paramount.

Safety and Collaboration

Ensuring the safety of human workers is a fundamental principle in industrial robotics. Collaborative robots, also known as cobots, are designed to work alongside humans in a shared workspace without the need for safety barriers. These robots are equipped with sensors and software that enable them to detect and respond to human presence, reducing the risk of accidents and improving overall workplace safety.

Efficiency and Productivity

Industrial robots are designed to optimize production processes by streamlining operations, reducing cycle times, and minimizing downtime. By automating repetitive and labor-intensive tasks, robots can significantly increase efficiency and productivity in manufacturing facilities. This principle is crucial for businesses looking to stay competitive in today’s fast-paced market.

The Future of Industrial Robotics

As technology continues to advance, the principles behind industrial robotics will evolve to meet the changing needs of the industry. Innovations such as artificial intelligence, machine learning, and advanced sensors will further enhance the capabilities of robots, paving the way for a new era of smart manufacturing. Embracing these principles and staying abreast of technological developments will be key to unlocking the full potential of industrial robotics in the years to come.

In conclusion, the principles behind industrial robotics form the foundation of a transformative technology that is reshaping the manufacturing landscape. By focusing on adaptability, precision, safety, efficiency, and innovation, industrial robots are poised to drive the next wave of industrial revolution. Understanding and applying these principles will be essential for businesses seeking to harness the full power of automation and robotics in their operations.