Material Composition and Properties

When choosing between FEP and PTFE tubing for your application, it’s essential to understand the chemical composition and physical properties of each. Both materials are fluoropolymers known for their excellent resistance to heat, chemicals, and electrical conductivity. However, their differences make them suitable for different use cases.

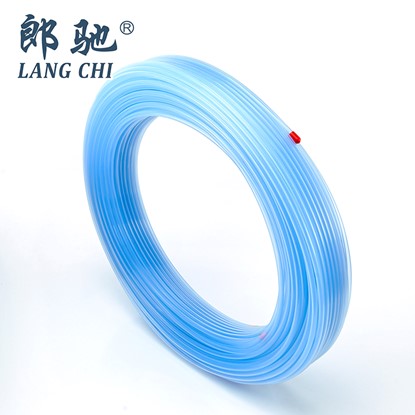

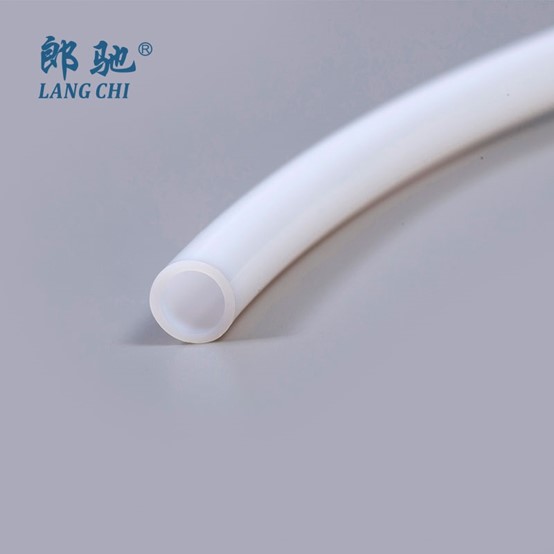

FEP (Fluorinated Ethylene Propylene) is a copolymer of hexafluoropropylene and tetrafluoroethylene. It retains many of the excellent properties of PTFE but offers better clarity and flexibility. PTFE (Polytetrafluoroethylene), on the other hand, is a homopolymer and is often more rigid and resistant to extremely high temperatures.

Application Suitability

Deciding between these two types of tubing depends greatly on the nature of your project. For example, FEP tubing is ideal for applications requiring visibility, such as fluid transfer lines where it’s helpful to observe the material flow. It is easier to work with in terms of bending and installation due to its greater flexibility.

Conversely, if your project involves sustained exposure to very high temperatures or aggressive chemicals, then PTFE may be the better option. High Temperature PTFE Tube is known for its ability to operate in environments exceeding 260°C without degradation, making it suitable for highly demanding industrial and laboratory settings.

| FEP | PTFE |

| offers better optical clarity, making it ideal for monitoring fluid levels | excels in environments with high thermal or chemical stress |

| is easier to thermoform and weld, which simplifies custom installations | has a higher melting point and slightly better chemical inertness |

Choosing Based on Project Requirements

Before selecting a tube type, assess the critical factors for your application. These may include flexibility, temperature tolerance, chemical compatibility, transparency, and ease of installation. For instance, when building a 3D printer that requires consistent and precise material flow, PTFE Tubing for 3D Printer is often favored due to its thermal resistance and non-stick properties.

However, if your system needs more pliability or will be regularly monitored, the transparency and flexibility of FEP tubing might outweigh the slightly better performance characteristics of PTFE. In some cases, a combination of both may even be ideal: using PTFE for high-stress zones and FEP for lines requiring visual monitoring.

- Evaluate the maximum temperature your system will reach.

- Consider whether visual monitoring of fluid or gas flow is important.

- Determine if frequent bending or movement will affect tubing longevity.

- Account for chemical exposure in the environment where the tubing will operate.

Ultimately, both FEP Tube and PTFE Tube offer excellent performance in industrial, laboratory, and consumer applications. The right choice depends on your project’s specific conditions and requirements. Consider performance trade-offs such as flexibility versus thermal resistance, and clarity versus mechanical strength, to make the most informed decision for your setup.