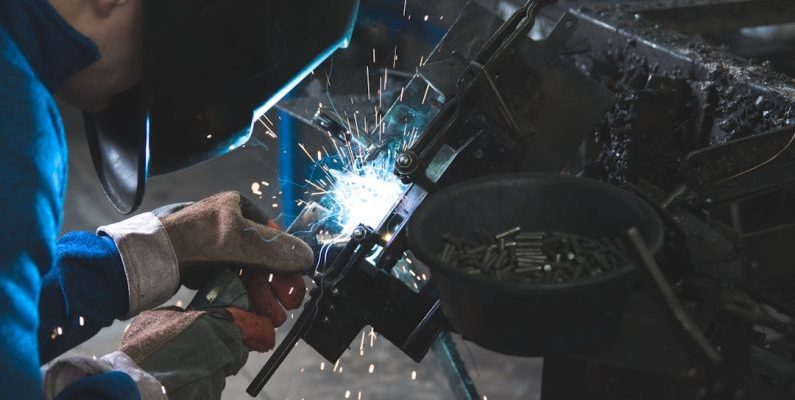

Metal fabrication is a complex process that involves shaping and transforming raw metal materials into various structures and products. One crucial aspect of metal fabrication is heat treatment, a process that plays a significant role in enhancing the properties and characteristics of metal components. From improving strength and durability to altering hardness and ductility, heat treatment is a vital step in the metal fabrication process that can have a profound impact on the final product.

Enhancing Strength and Durability

One of the primary reasons why heat treatment is essential in metal fabrication is its ability to enhance the strength and durability of metal components. By subjecting the metal to controlled heating and cooling processes, the internal structure of the material can be altered, resulting in improved mechanical properties. Through techniques such as annealing, quenching, and tempering, metal fabricators can tailor the strength and hardness of the metal to meet specific requirements, making it more resistant to wear, fatigue, and deformation.

Improving Machinability and Formability

In addition to enhancing strength, heat treatment also plays a crucial role in improving the machinability and formability of metal components. By carefully controlling the temperature and cooling rate during the heat treatment process, metal fabricators can modify the microstructure of the material, making it easier to machine, bend, and shape. This is particularly important in industries such as automotive and aerospace, where complex metal parts must be manufactured with precision and efficiency.

Altering Hardness and Ductility

Another key benefit of heat treatment in metal fabrication is its ability to alter the hardness and ductility of the material. Through processes such as quenching and tempering, metal fabricators can achieve a balance between hardness and ductility, ensuring that the final product exhibits the desired mechanical properties. By controlling the transformation of the metal’s crystal structure through heat treatment, fabricators can tailor the hardness and toughness of the material to suit its intended application.

Enhancing Corrosion Resistance

Heat treatment also plays a vital role in enhancing the corrosion resistance of metal components. By creating a protective oxide layer on the surface of the metal through processes like nitriding and carburizing, fabricators can increase the material’s resistance to rust, oxidation, and other forms of corrosion. This is particularly important in applications where metal parts are exposed to harsh environments or corrosive substances, ensuring the longevity and reliability of the final product.

In conclusion, heat treatment is a crucial step in the metal fabrication process that offers a wide range of benefits, from enhancing strength and durability to improving machinability and corrosion resistance. By understanding the principles of heat treatment and its impact on metal properties, fabricators can produce high-quality components that meet the demands of various industries and applications.